ASTM F2878

Hypodermic Needle Puncture Testing for Protective Clothing

Needlestick injuries pose a significant health risk, potentially exposing individuals to bloodborne pathogens like HIV and Hepatitis B and C. Protective gloves, clothing, and other materials must undergo rigorous testing to verify their puncture resistance. ASTM F2878 establishes a standardized procedure to measure this resistance, aiding manufacturers in developing safer products and helping regulatory bodies enforce protective standards.

ASTM F2878 and Its Importance for for Protective Clothing

ASTM F2878 is a standard test method used to evaluate the puncture resistance of protective clothing materials against hypodermic needles. This testing is crucial in industries where hypodermic needle puncture testing ensures the effectiveness of protective gear for medical professionals, law enforcement personnel, and industrial workers. The method provides a standardized approach to determining how well materials resist penetration, directly influencing worker safety.

ASTM F2878 - Puncture Resistance for Protective Clothing

Hypodermic Needle Puncture Testing Method

The ASTM F2878 test involves placing a material specimen in a support assembly and subjecting it to needle penetration at a constant velocity. The test measures the maximum force required to puncture the material, providing an accurate assessment of its protective capabilities.

- A specimen is secured in a testing apparatus.

- A hypodermic needle (typically 21G, 25G, or 28G) is affixed to a load cell.

- The needle moves perpendicular to the material until penetration occurs.

- The maximum force required to puncture the material is recorded.

- Results are averaged from twelve test replicates to determine puncture resistance.

Choosing the Right Needle Puncture Tester

Equipment Used in ASTM F2878 Testing

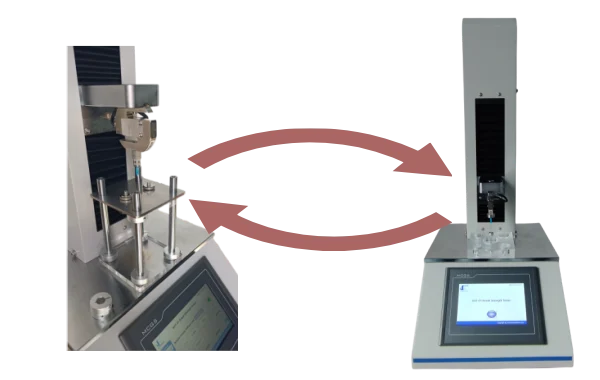

The testing requires specialized needle puncture tester like the Puncturetest.com NPT-01 Needle Puncture Tester, which ensures precise measurements. The apparatus must have:

- A secure specimen holder to prevent slippage.

- A calibrated load cell to measure penetration force accurately.

- Various needle sizes to simulate real-world puncture risks.

- A constant-speed mechanism for uniform test conditions.

When selecting a hypodermic needle puncture tester, key factors include:

- Test speed adjustability for various materials

- Compatibility with multiple needle types

- High-precision load cells for accurate force measurement

- User-friendly interface for easy operation

The Puncturetest.com NPT-01 Needle Puncture Tester meets ASTM F2878 standards and offers customizable features for diverse testing needs. Its advanced PLC control system and precision ball screw mechanism ensure repeatable and reliable results.

Applications of Needle Puncture Resistance Testing

Importance in Protective Clothing

The hypodermic needle puncture test is particularly significant for industries where sharp object exposure is a risk. Protective clothing materials evaluated under ASTM F2878 include:

Medical gloves and gowns (used in healthcare settings)

Law enforcement gear (for protection against needle attacks)

Industrial protective suits (for handling hazardous materials)

Laboratory PPE (to prevent accidental needle exposure)

Compliance with Safety Regulations

Many industries require compliance with ASTM F2878 to ensure workers are protected against needle-stick injuries. This is especially relevant for:

OSHA guidelines on workplace safety

FDA regulations for medical protective equipment

ISO standards for personal protective clothing

Ensuring these materials meet the required puncture resistance standards minimizes occupational hazards and enhances safety.